My Chemical Engineering Journey

Modern Problems

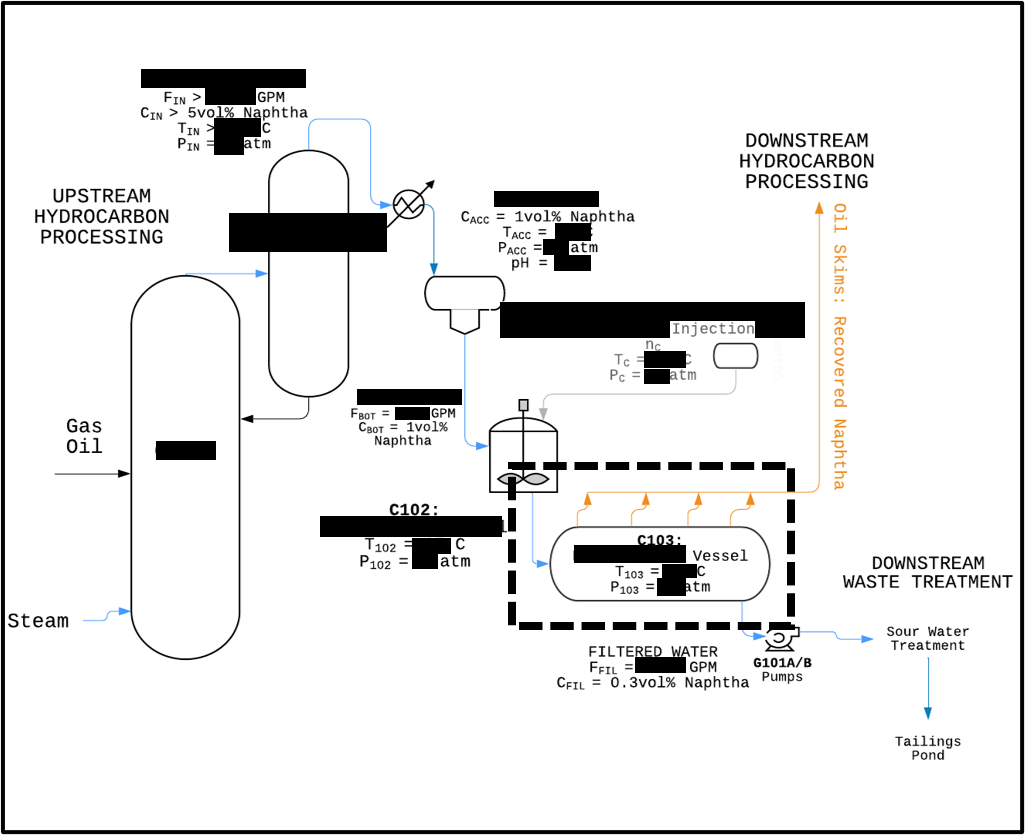

There are currently 1.5 trillion liters of tailings in Northern Alberta’s tailings ponds. Water used in the processes may be contaminated by small traces of emulsified hydrocarbons which is eventually carried into the open ponds. These hydrocarbons may present some risk to the surrounding wildlife and is essentially wasted. These ponds are also a significant economic liability since it is required by Albertan law to recover the pond after 10 years of its inception.

Inspiration

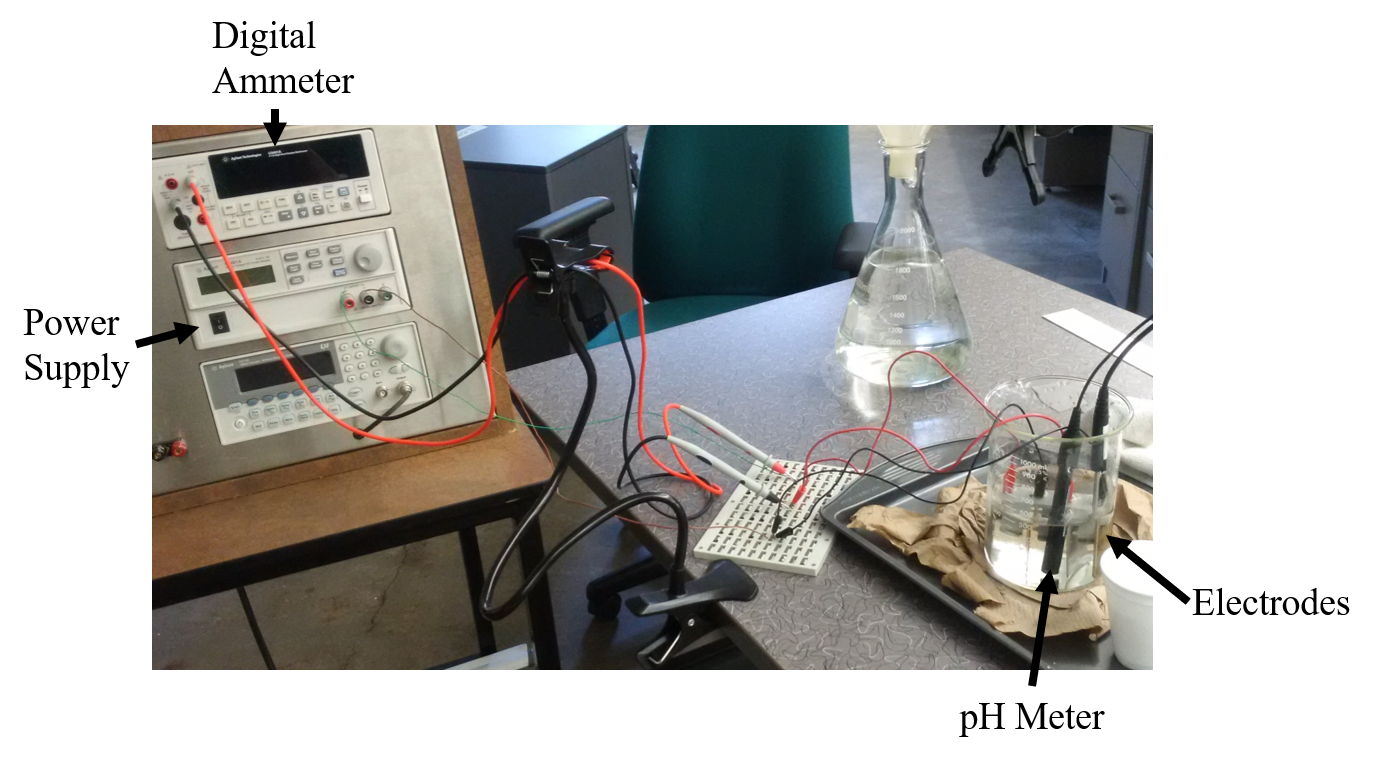

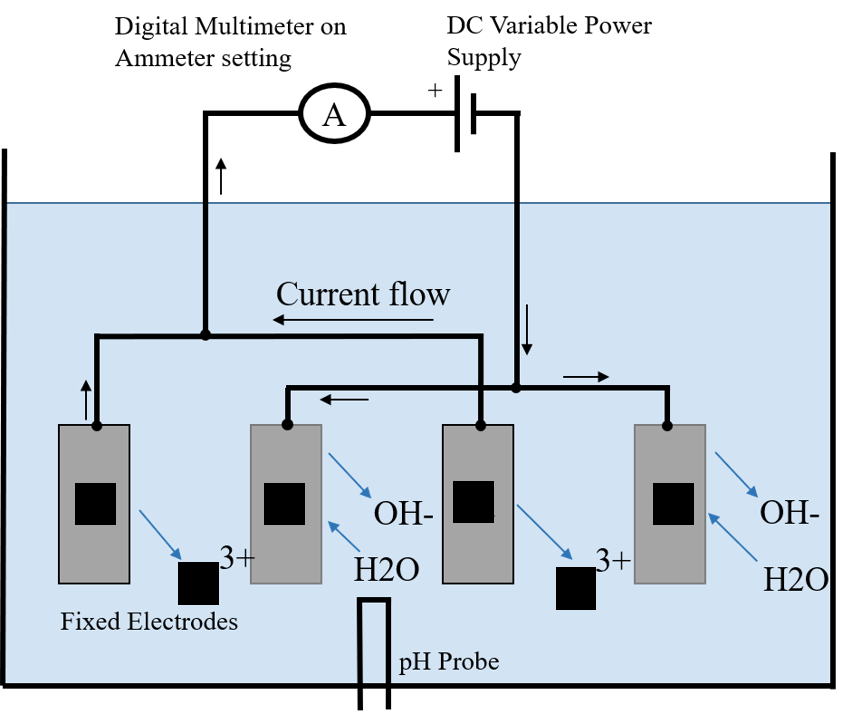

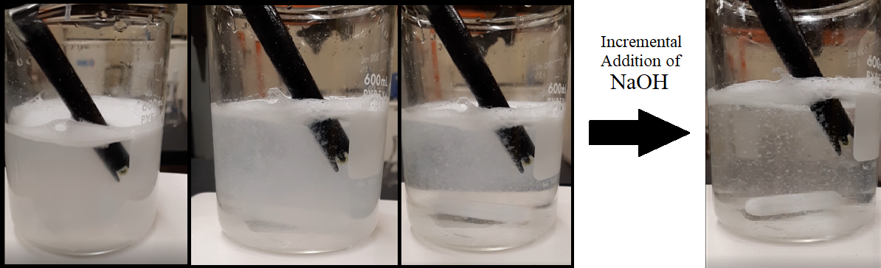

As part of a 2nd year project, I learned of a technology which used ********** to purify water of suspended waste matter. I explored this tech with a makeshift electrolytic cell.

By passing a current between a ***** anode and ***** cathode, I dissolved ***** and hydroxide ions in the dirty solution while producing a hydrogen gas biproduct.

The exact theory behind this process is a trade secret ;). However, this process can be as part of a water purication process.

Application

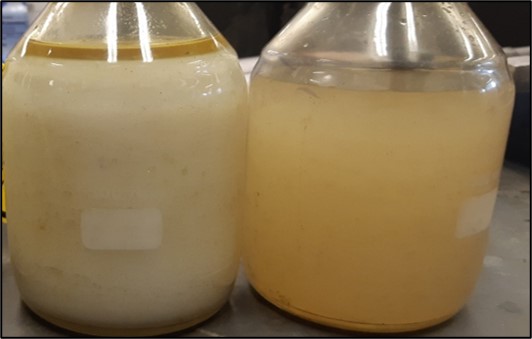

While working in the Oil Sands industry, I discovered a useful application for this technology. Here, water is often used for a number of reasons. The resulting contamination is due to the suspension of microdroplets. Shown below is water contaminated with static oil droplets. These oil droplets eventually end up in the tailings.

4rth Year Capstone

I pitched the idea of purifying oil sands waste water to my capstone team and with unanimous agreement, we all set off to tackle this issue. I was designated leader of the project and was personally responsible for ensuring that all of the theory and proposals lined up. I took responsibility for any missed concepts or misconceptions. I frequently coordinated my team to ensure that everyone knew what direction we were headed and for what timeline. With the allocated time, our group explored two competing solutions.

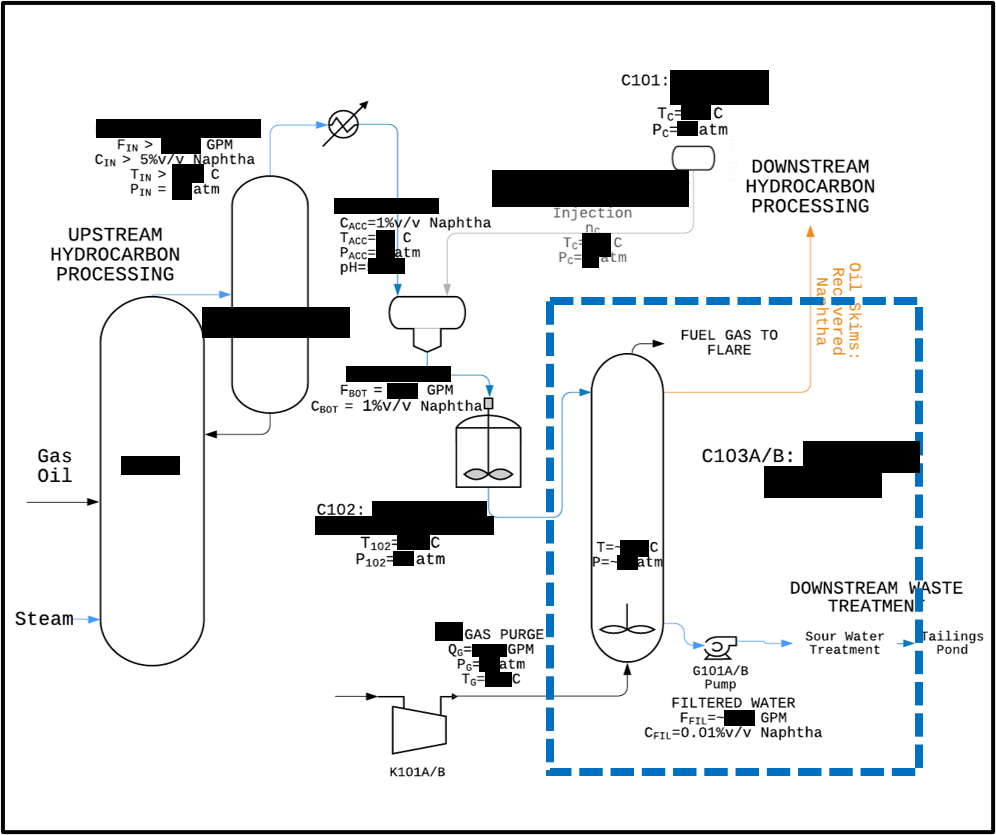

The first solution suggests the implementation of counter-current ********** to purge the downflowing waste water stream.

The second solution suggests using a spacious ********** for chemical **********.

Significance

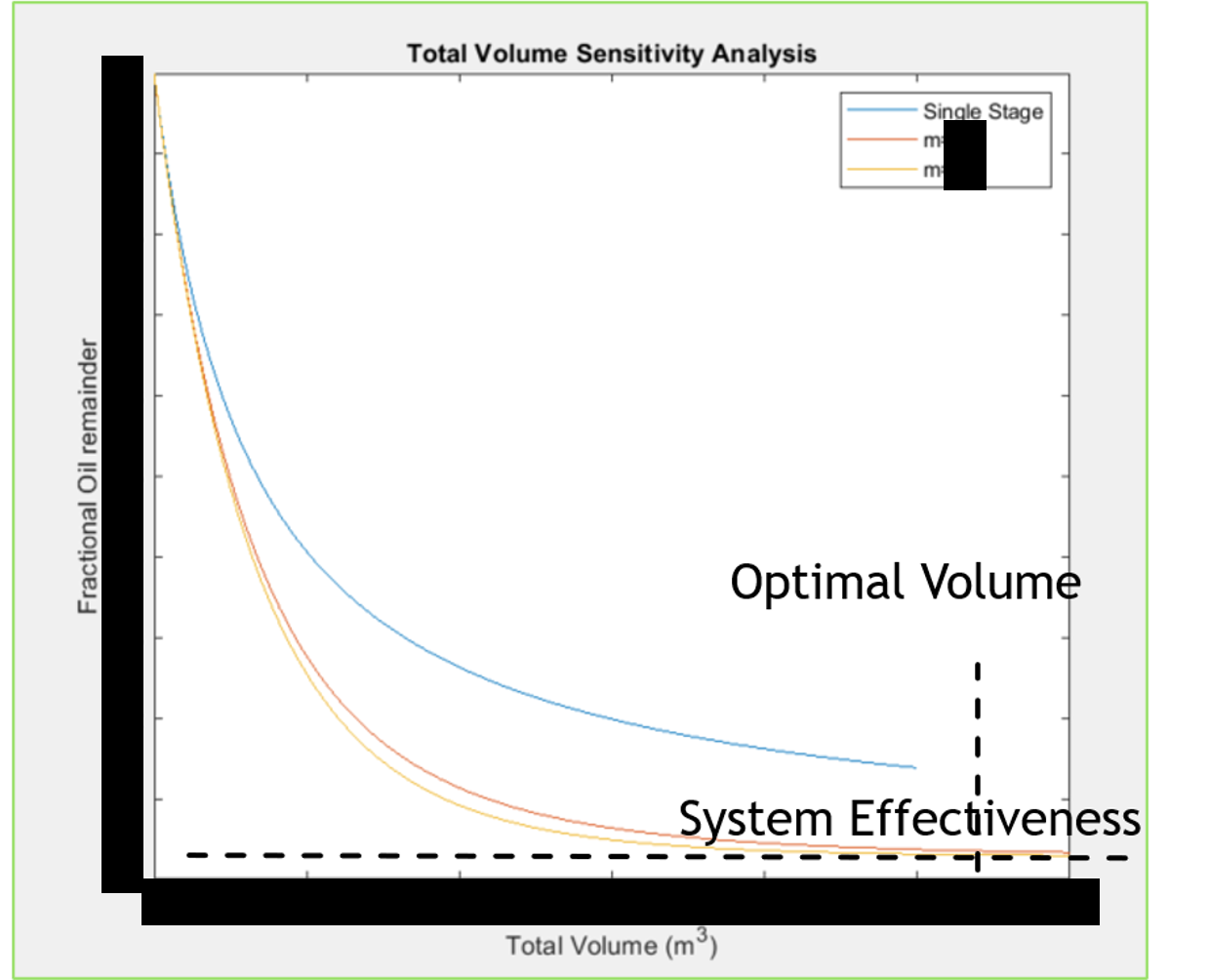

Between the two proposed solutions, we found that it was possible to recover up to at least $11 million CAD worth of oil in the assumed 5 year lifespan of this project. The project would break even within 1 year even if it were to operate with an abysmal recovery of 40% compared to the expected 90% recovery rate.

This process could achieve even higher recovery rates of 95% or more with proper optimization!

Safety and Insurance

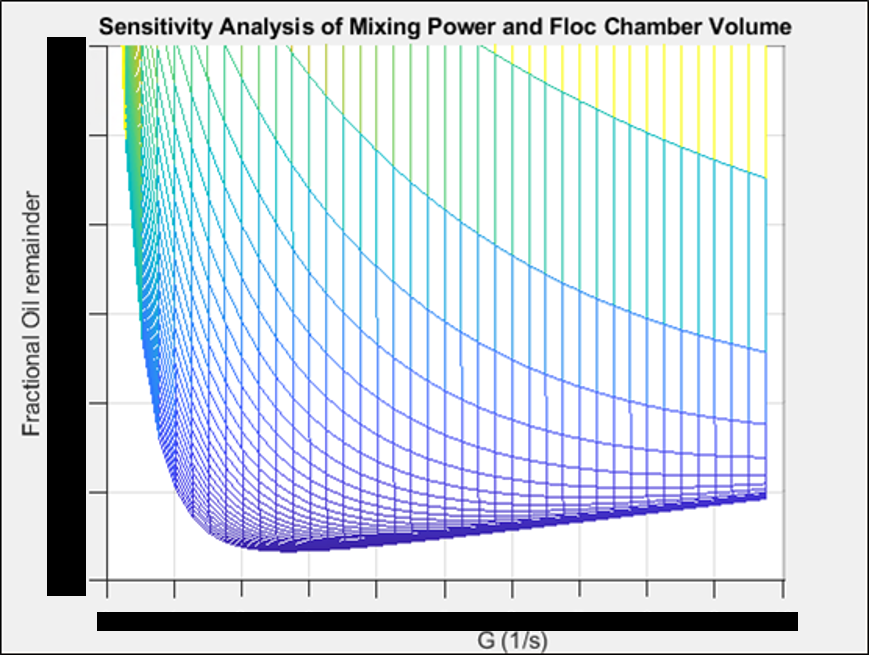

The beauty of this technology is that it is robust. Even if our system effectiveness parameters were off by a magnitude of 100 due to high turbulence or other process factors, it would still be possible to maintain continuous effective recovery.

Furthermore, the reagents used for this auxilary process is environmentally friendly and proposed in small amounts. In fact, the project has a 100% KPI score in 9 out of 11 categories due to nature of the purification technology.

Lessons Learned

In this journey, I developed a deep appreciation for team members of different mindsets. I learned the importance of assigning my team members to roles which suited their strengths. I also learned the importance of carefully considering the advice of my other team members. There were times in which individual team members have saved the team from going down ambitious rabit holes for which we did not have the time. Our own head of marketting kept us focused on achieving financial business goals while the rest of the team could build the technical scaffolding to support these goals.